Progress on the 6502 computer – Milling PCB’s

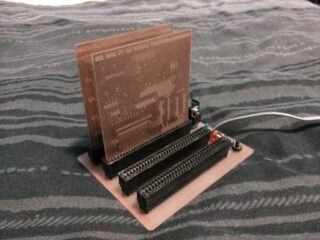

While work and other commitments have been sapping a large amount of my time I have been making slow progress with the milling of circuit boards for the 6502 computer project. I have added some pictures of progress below.

I am slowly getting the hang of repeatable and reliable results on the mill. Most trouble stems from the height at which the program starts: Cut too deep and the V cutter wears quickly, the tracks wander a bit (following the weave of the fibreglass mesh in the board) and the over all finish is poor. Cut too shallow and you might run into issues with track isolation.

I seem to have found a sweet spot for starting position and depth of cut specified in the GCode, there are methods for using a probe to set height but I have been using some thin thermal docket paper to test height. I carefully jog the Z axis down until the V cutter just cuts the paper without marking the surface of the copper, I hit the “touch off axis” button to set the zero position and then run the program.

I am still tweaking the design of the boards but I am very close to the final revision. Once this is done I can start milling the final version of the boards and begin construction.